Steel Melting Furnace Companies

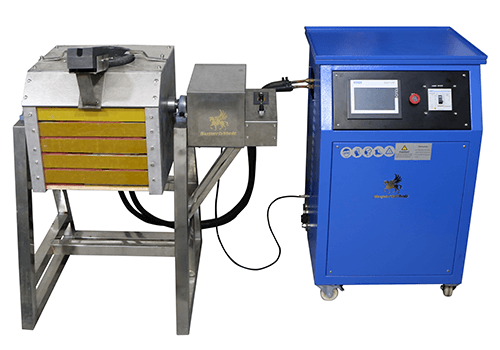

The induction furnace gets the job done quicker efficiently and it is also cost effective.

Steel melting furnace companies. This gave us invaluable experience in designing rugged heat treating equipment. During world war ii mifco began a commercial heat treating operation for almost two decades. Put the metal you want to melt inside the crucible and use a pair of fire tongs to set it in the middle of your furnace. Steel melting furnace we are engaged in manufacturing a wide range of induction melting furnaces that caters to the demands of steel industry.

Most steel plant companies using induction furnaces find it the most convenient method for melting metals. For high melting point alloys such as steel or nickel based alloys the furnace must be designed for temperatures over 1 600 c 2 910 f. Precious metal melting furnace unlike any other metal treating kiln on the market the quikmelt pro series top loading kilns weigh just 10 lbs and fire up to 2200 f 1205 c. Electricity propane or natural gas are usually used to achieve these temperatures.

Allow the furnace to heat the crucible and melt the metal before taking it out with tongs for casting. For low temperature melting point alloys such as zinc or tin melting furnaces may reach around 500 c 932 f. This is because of the many benefits of induction furnace. Early features that set apart from competitors were the attention to safety and the ability to get quick melts.

Mifco was started in 1938 as a supplier of foundry equipment to the vocational field. With 1500 watts of power a standard household plug and exclusive rapidheat technology enabling full firing in as little as 8 minutes the quikmelt pro is the ultimate. Superbmelt metal melting furnaces are widely used in various of metals smelting such as gold silver copper platinum etc from 1kg to 250kg. Stainless steel smelting furnace if power induction heating the power range of 15kw 200kw.

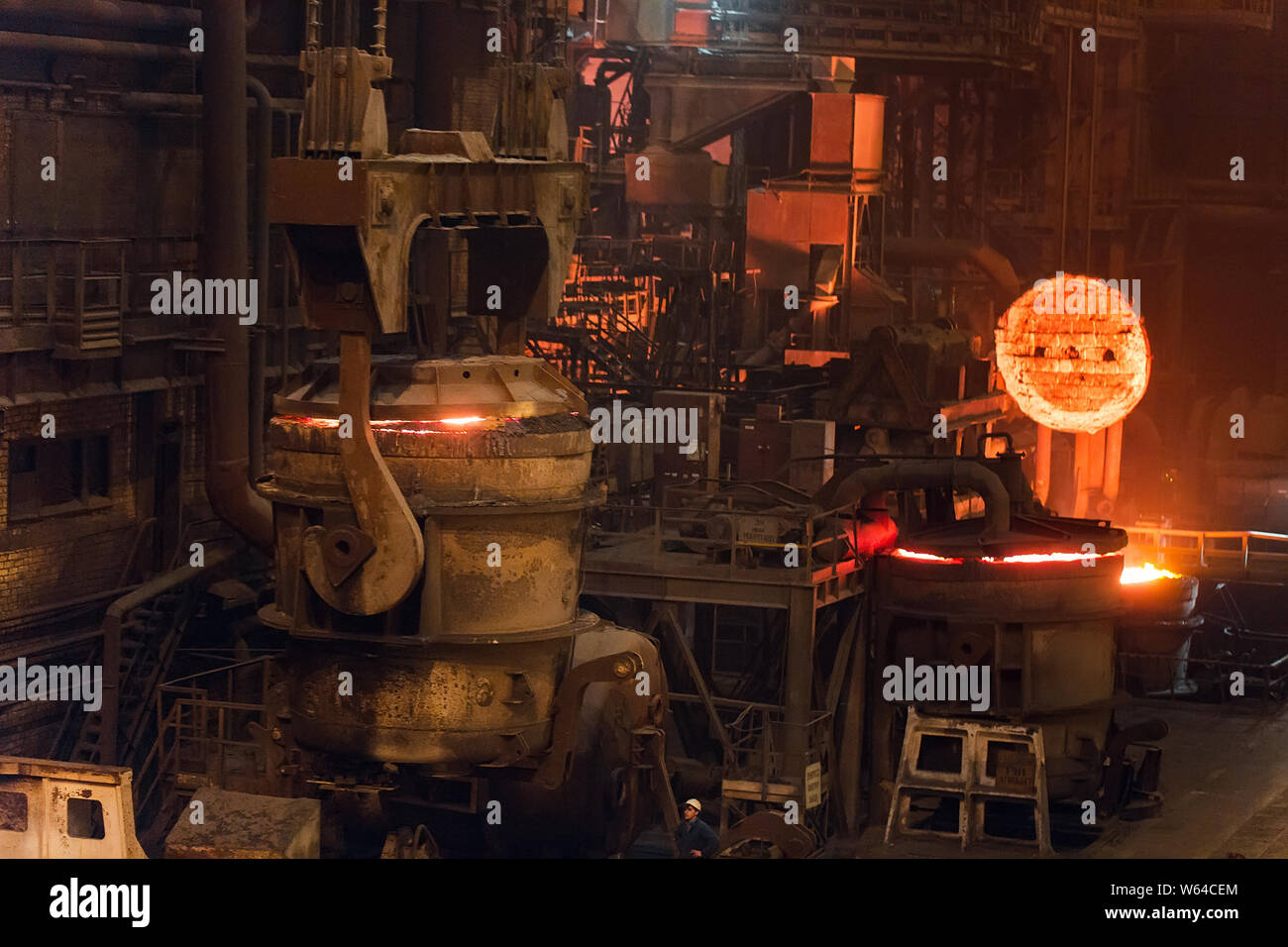

We are also manufacturing melting furnace which include lead melting aluminium melting copper melting brass melting zinc melting silver and gold melting or melting of any material whose meting temperature is below 1200 deg c. The high performing 120 ton electric arc furnace is the result of choosing the best technology such as ultra high power 130 mva transformer design which allows to operate the furnace at high secondary voltage and a longer arc resulting in shorter processing times for melting heat. Adopt igbt induction technology and optional plc control system to achieve speedy melting and accurate temperature control. The company specializing in the production of small scale melting furnace the energy saving electric melting furnace equipment melting furnace easy operation environmental pollution is the ideal steel melting furnace equipment small size light.