Solvent Recovery Systems Uk

The recovery of solvents from effluent can be achieved with a variety of technologies.

Solvent recovery systems uk. Solvent recovery is the process of extracting useful materials from waste or by product solvents generated during the manufacturing process. These chemicals can then be repurposed reducing the need to produce new solvents while eliminating a large amount of waste and removing potentially hazardous substances from what s left. The solvent recovery and recycling systems then switches off and is ready for manual or fully automatic emptying. Pathtrue laboratory solvent recycling and recovery systems.

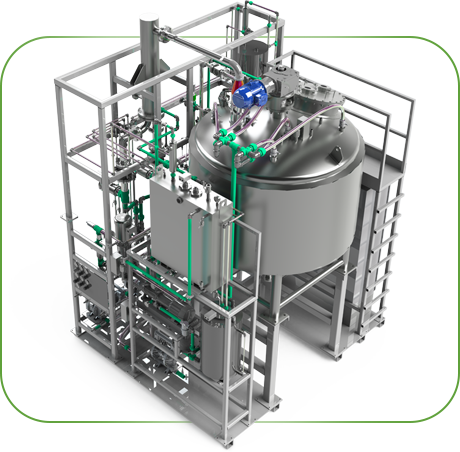

Solvent availability is paramount in a laboratory setting. Our solvent recyclers promote sustainability safety operational improvements and process automation in the form of higher throughput as well as quality results and cost. A solvent recovery system is a process system that takes effluent and extracts useful solvents and raw materials back out of the process waste stream. The solution is boiled and the vapors are condensed back into liquid in a separate tank very similar to how a vapor degreaser works.

The distilled or purified solvent flows continuously from the solvent recovery and recycling systems into the customer s on site tank. Rhs solvent recovery systems successfully reduce waste and increase profits with typical roi of less than 1 year. A new solvent recovery system implemented by promethean particles at its uk plant is enabling the recovery and reuse of more than 95 of organic solvents the company uses to manufacture some of its high specification nanomaterials. With a range of solvent recycling machines from just 15 litre capacity everyone can recycle and save.

Solvent recovery systems use the process of distillation which separates volatile and nonvolatile solutions in a solvent. The various constituents of the solvent and contaminants each boil at different. Solvent recycling systems for every application using the distillation principle a solvent recycler separates the waste from the original solvent and recovers it for re use. Perfect scraper system in asc 1500 solvent recovery and recycling systems.

The rhs converts hazardous waste into 99 5 pure reusable solvent. A common recovery method is solvent distillation systems but liquid liquid extraction absorption systems. Cbg offers benchtop and cart mounted solvent recycling systems that achieve high purity while reducing solvent spend lab waste and disposal costs. The solvent recyling rhs still series is a continuous process solvent recovery still controlled by a plc.

.png)