Solvent Recovery System Design

Pollution control industries now tradebe environmental services llc of chicago illinois.

Solvent recovery system design. The rhs converts hazardous waste into 99 5 pure reusable solvent. Pesco has designed and built a 1 200 liter per hour hazardous industrial solvent recovery system for pci. In process solvent recovery is widely used as an alternative to solvent replacement to reduce waste generation. Front end engineering and solvent recovery system design are completed with epic as your project partners.

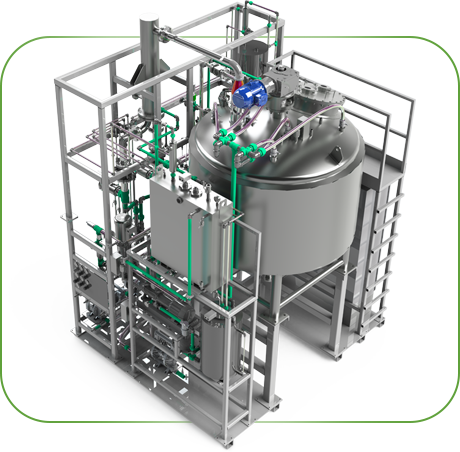

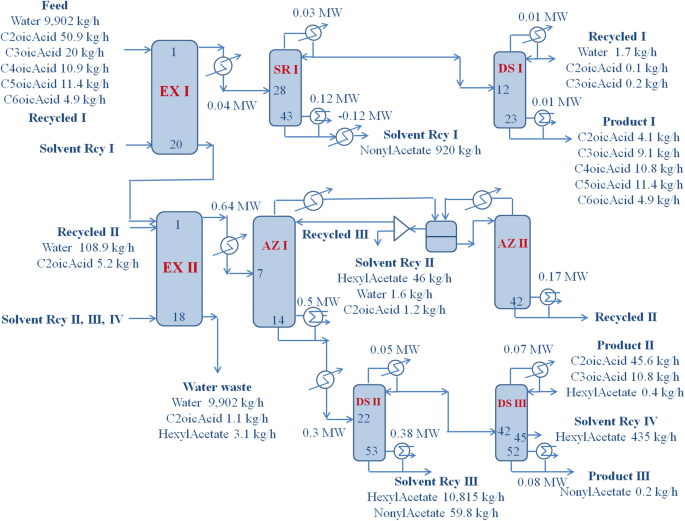

Specializes in the design and construction of complete modular process systems including solvent recovery applications our four decades of experience applying modular construction techniques and novel separation designs for a wide range of environmental waste applications ensures optimal solvent recycling systems for the specific needs of each client. Most solvent recovery systems are distillation applications and so the solvent recovery system design process follows a distillation design methodology. Koch modular process systems llc. Solvent recovery systems built by pesco.

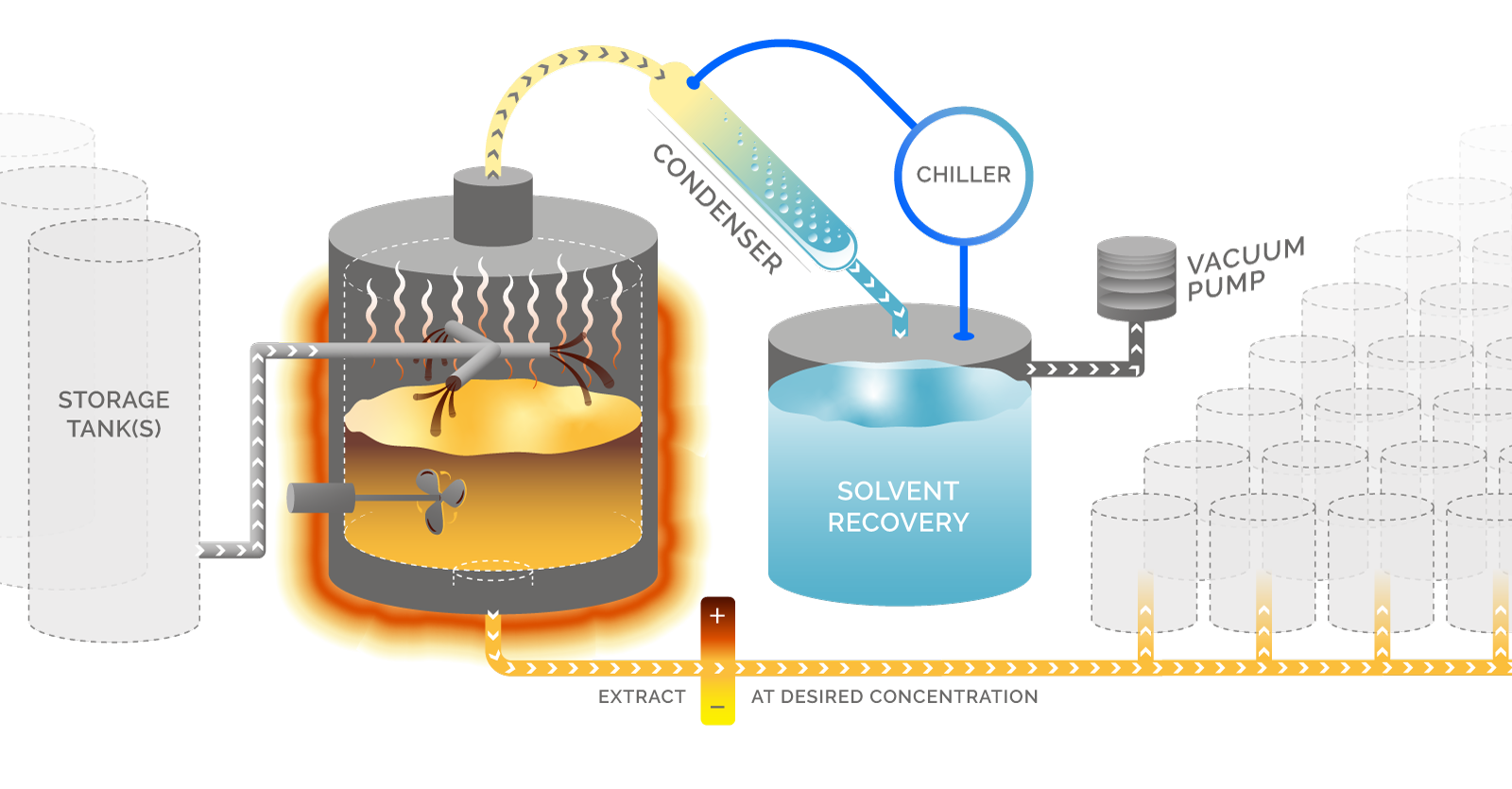

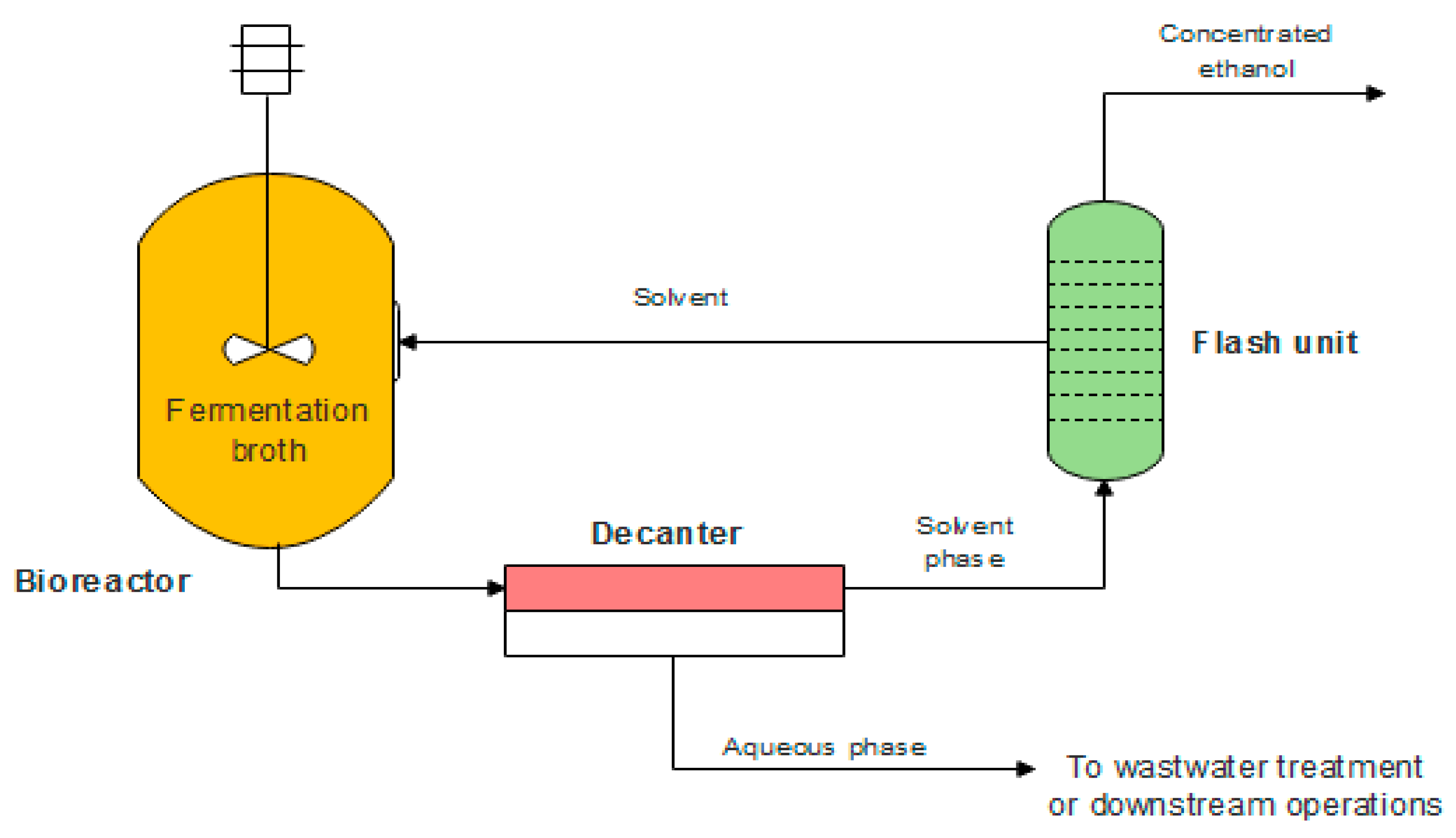

A thorough discussion of your solvent recovery goals budget and technology will help both parties determine if this project is a technical and commercial fit. Typical solvent recovery systems heat and distill waste fluids to boil off the solvent which is then collected as vapor and condensed cooled back down to liquid form for reuse. The solvent recyling rhs still series is a continuous process solvent recovery still controlled by a plc. It separates light hydrocarbons from a middle cut oils and heavy cut oils as well as from solids.

Solvent recovery is a form of waste reduction. There is widespread commercial availability of solvent recovery.