Solidworks Convert To Sheet Metal Greyed Out

Please subscribe our channel for more videos and project.

Solidworks convert to sheet metal greyed out. The sphere is based on the existing sheet metal parameters. For more information about solid. If an edge already has a fillet applied the radius of the fillet is used as the bend radius for the new sheet metal part. Create the solid part.

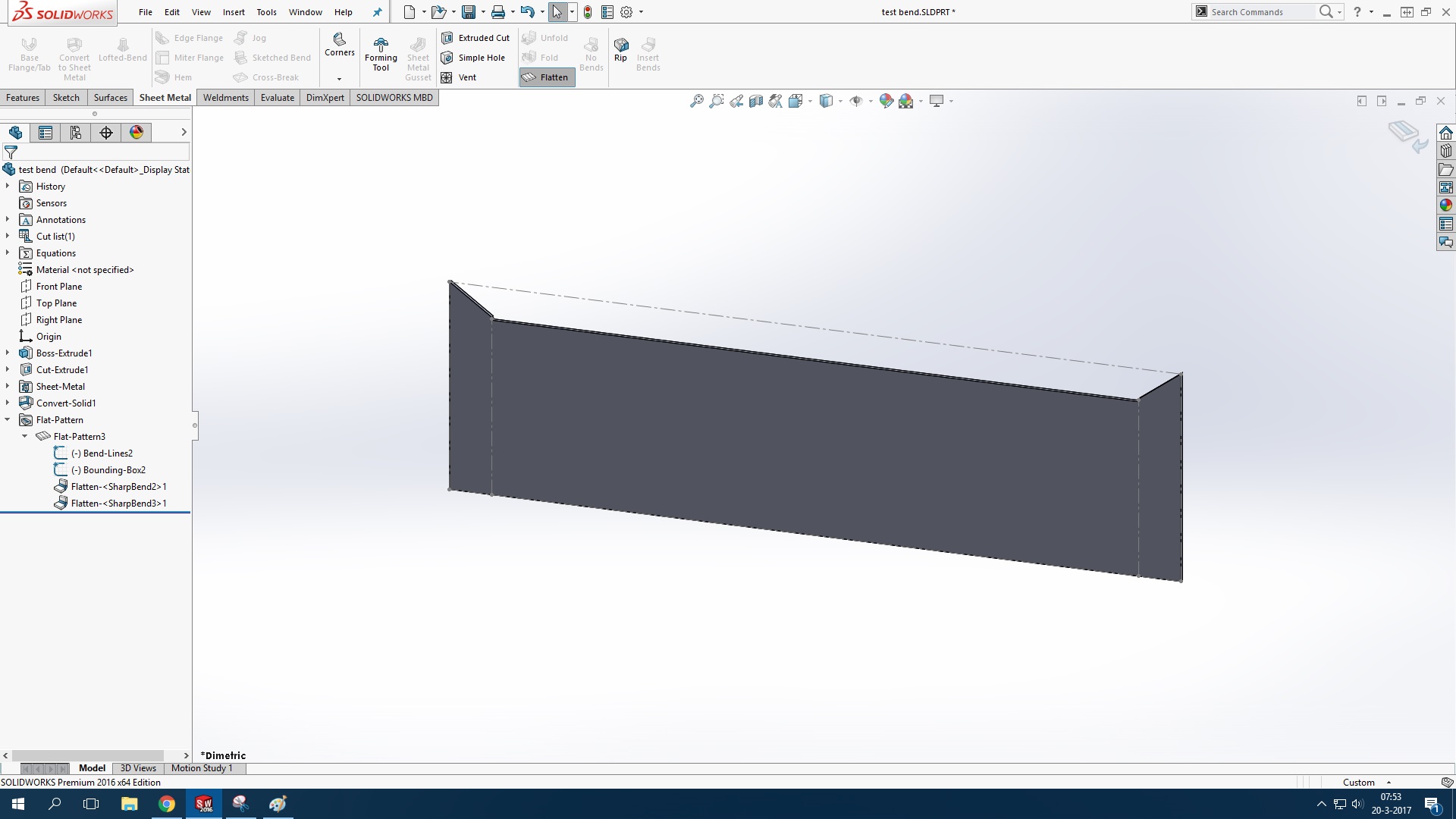

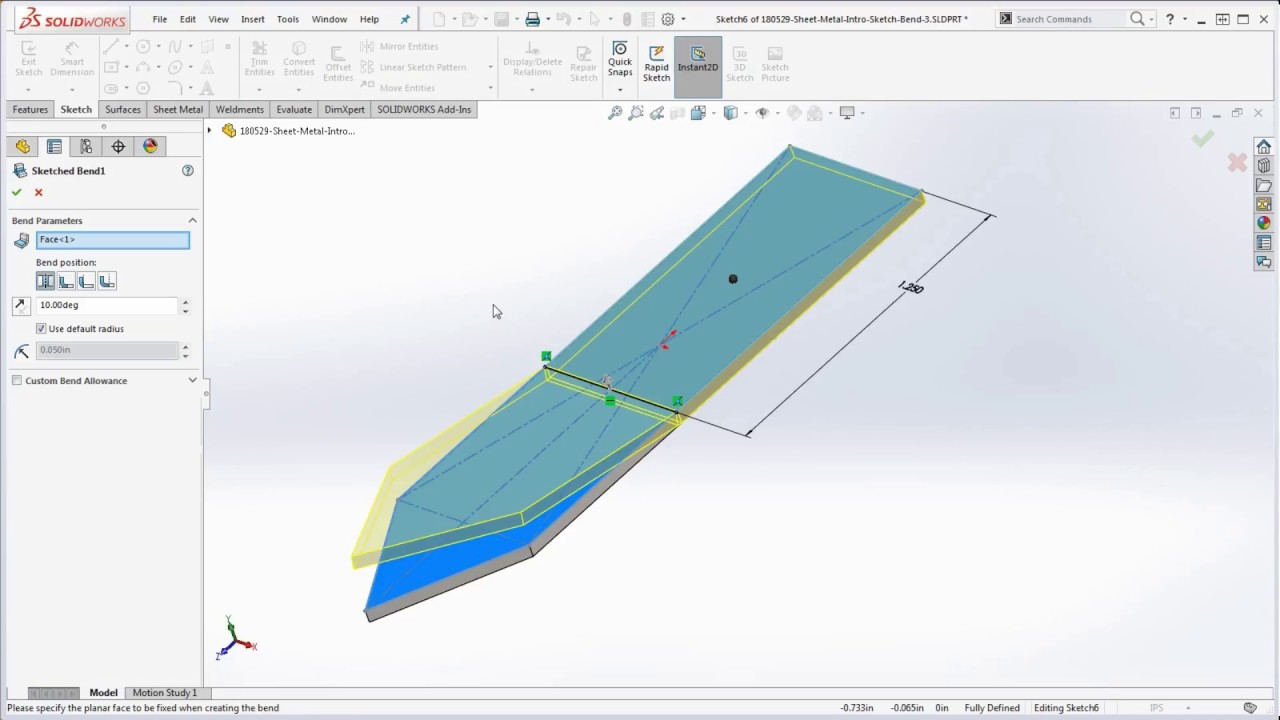

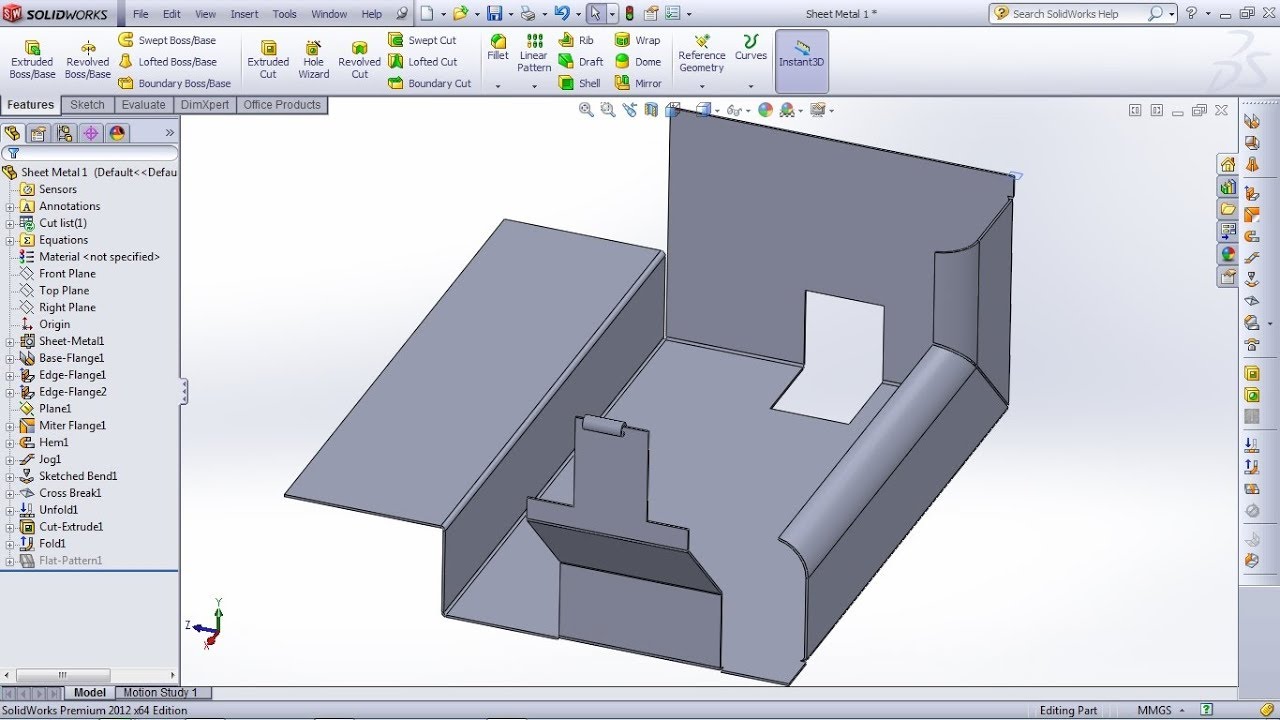

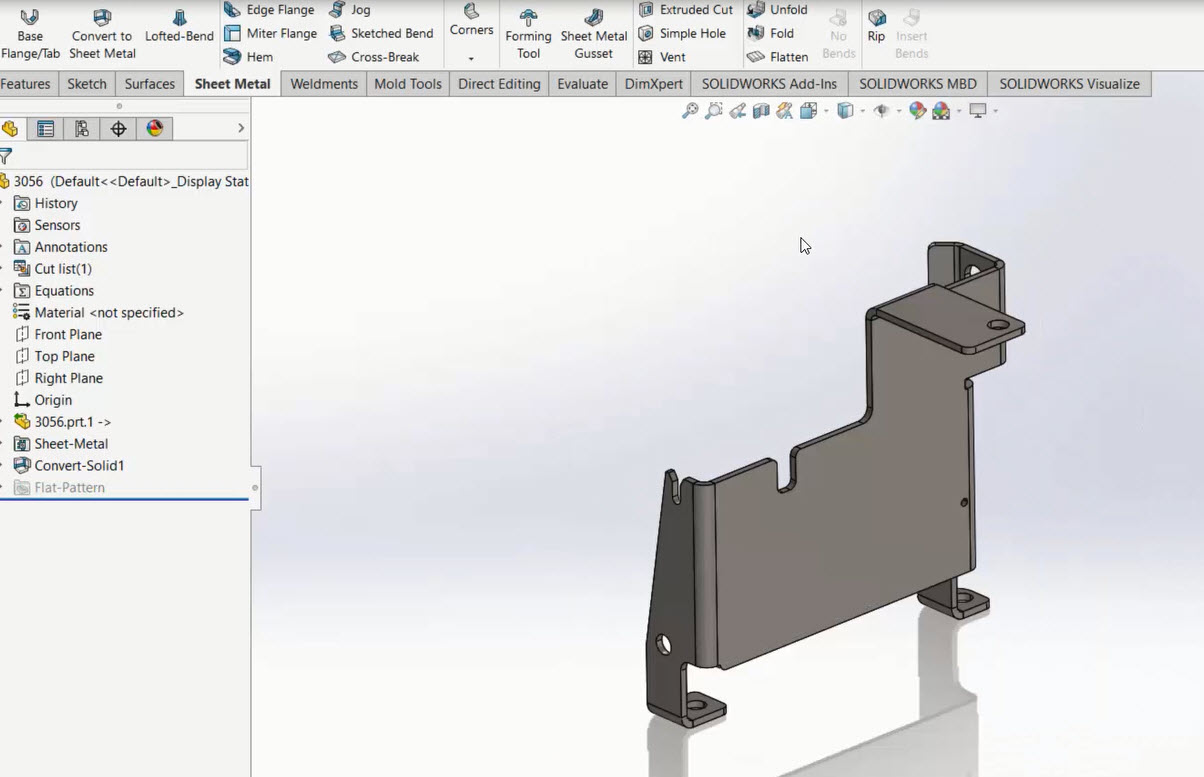

Leaves the gap unchanged. In the propertymanager under sheet metal gauges set options if you want to use a gauge table. This video shows the difference between creating a sheet metal part from scratch and converting a solid part to sheet metal. Click convert to sheet metal sheet metal toolbar or insert sheet metal convert to sheet metal.

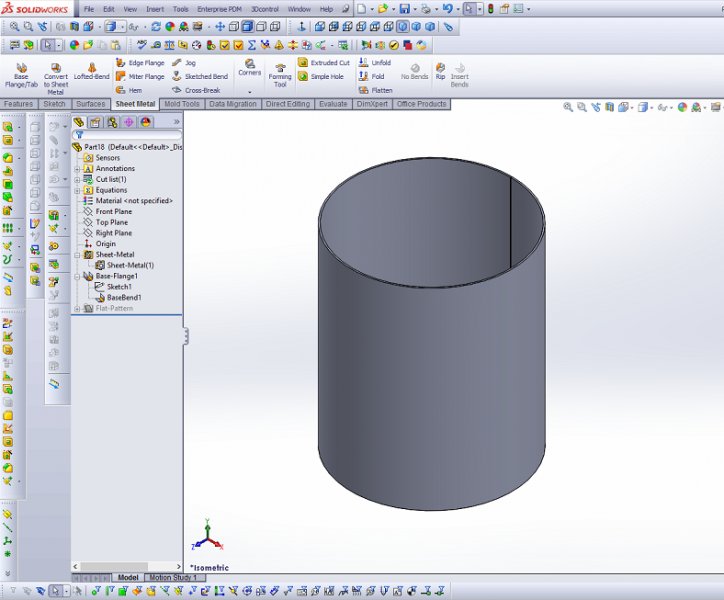

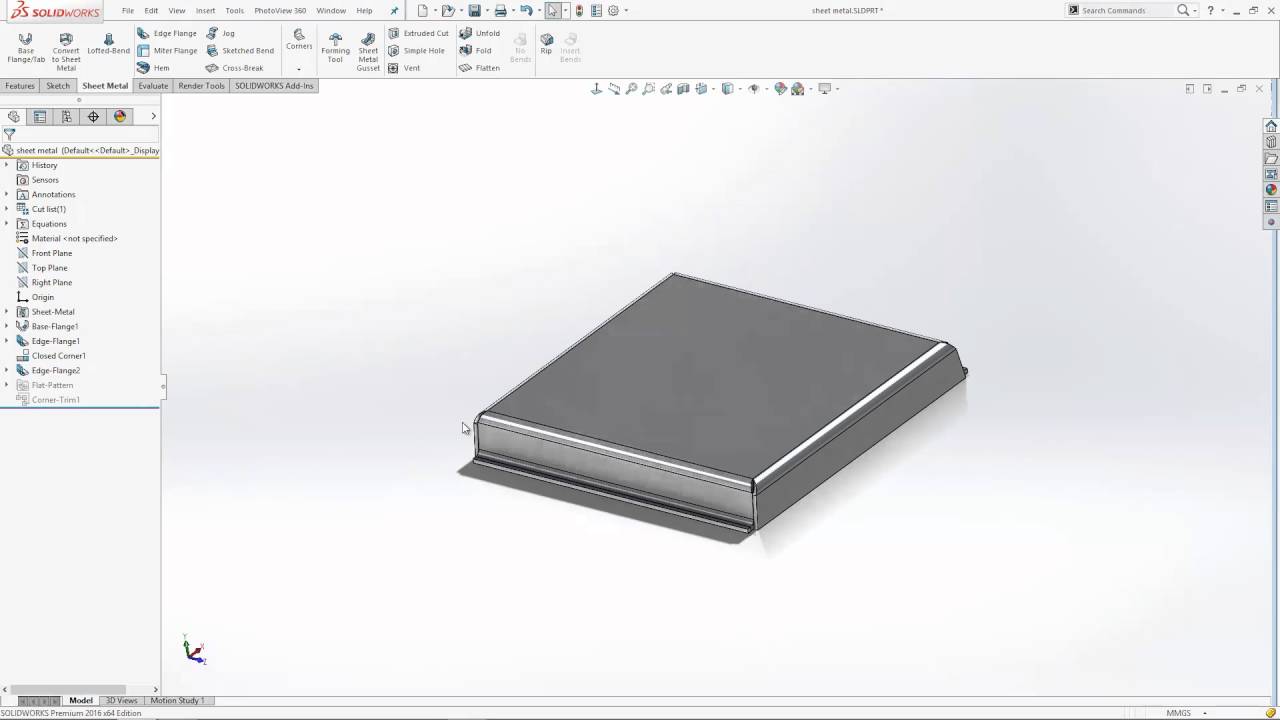

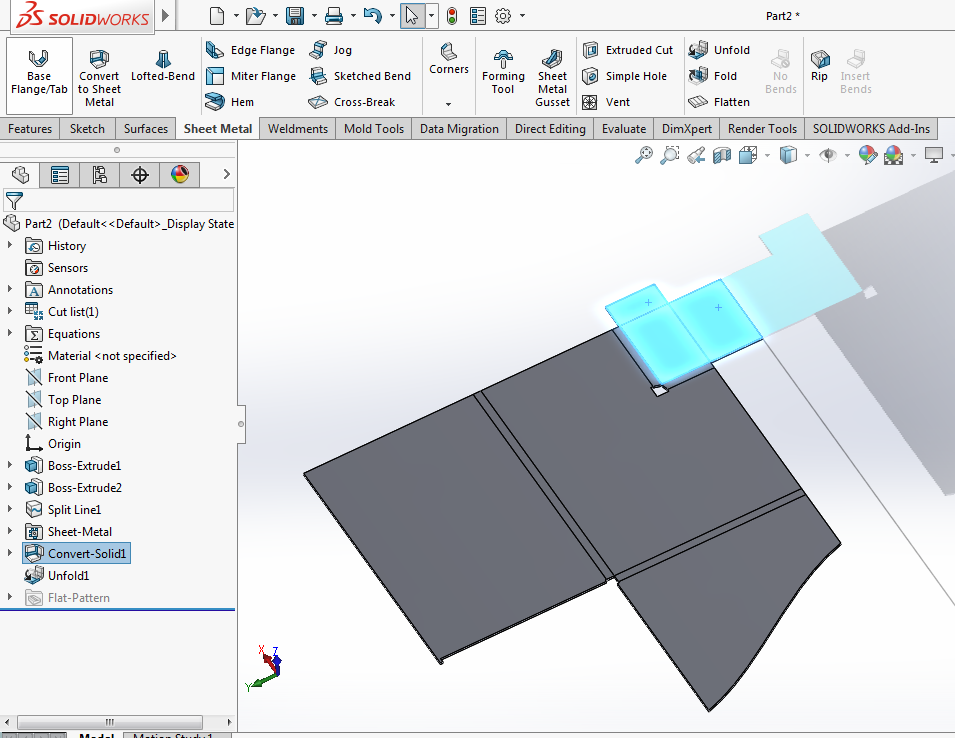

In this lesson you create the sheet metal part. Solidworks convert to sheet metal cylinder. 1 creating a base flange 2 adding a miter flange 3 mirroring the part and creating. Convert to sheet metal with split line to control one flange.

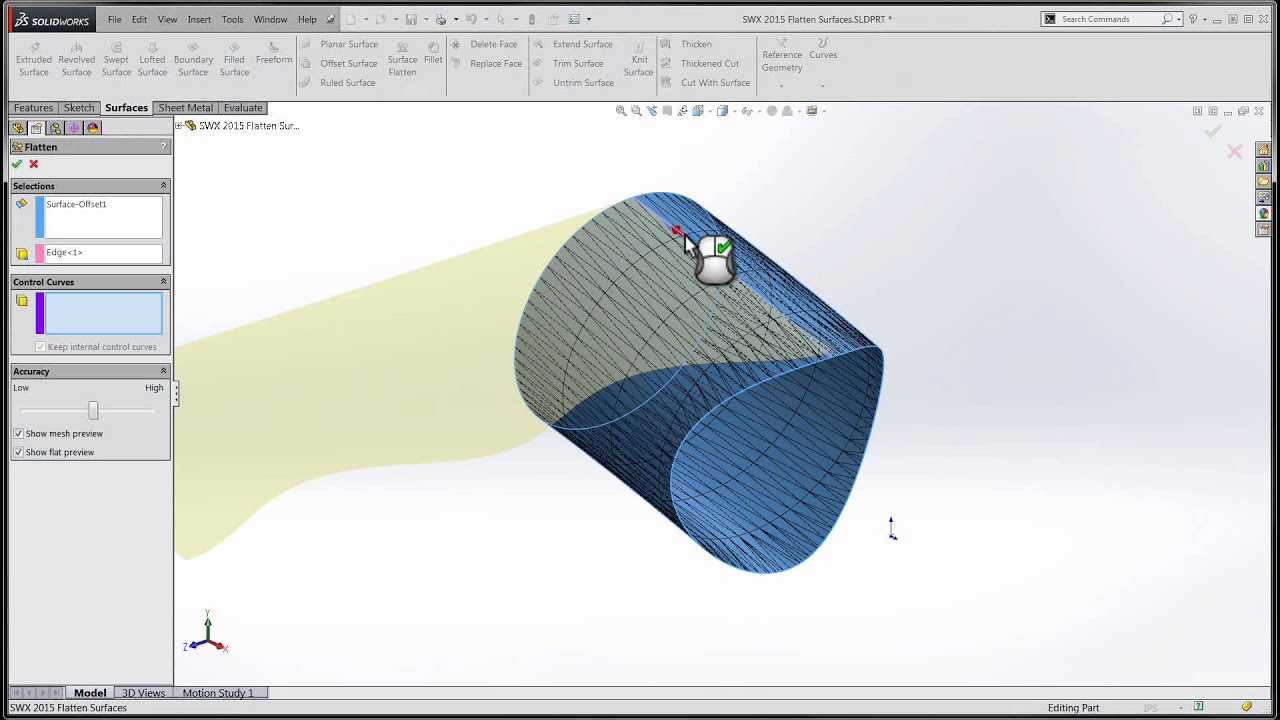

This tutorial shows how to convert cylindrical hollow solid part to sheet metal cylinder. Cuts the corner relief with the gap. How to convert 3d part into sheet metal in solidworks with the help of convert to sheet metal tools. Extend the gap into the bend area.

In the convert to sheet metal propertymanager you specify the fixed face and thickness of the sheet metal part the default bend radius and the edges or fillet faces on which to create bends. The software automatically selects the edges on which rips are applied. As shown in figure 4 the checkbox for keep body has been enabled in order to reuse the same body in case the bottom and back side need to be utilized for a multibody sheet metal design. Designers are not limited to only one sheet metal part.